Product Specification

| Brand | Wellbing Machinery |

| Condition | New |

| Warranty | YES |

Product Descriptions

Description:

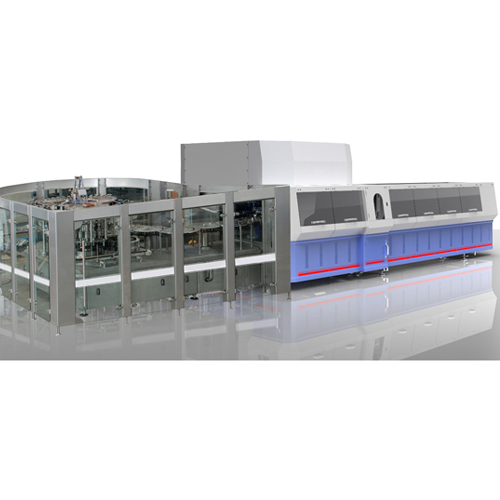

Wellbing blowing-filling-capping combi-block machine combines the blowing system, filling system and

capping system in one integrated system, reducing several intermediaries such as transmission, empty

bottle handling and storage processes, which improves packaging hygienic condition and reduces packaging

cross-contamination so as to improve the overall operating efficiency but lower the energy consumption, thereby

reduces the overall production cost of enterprises.

Product Range:

Production capacity from 12,000 BPH to 54,000 BPH.

Applications:

It is applied to PET bottled pure water, carbonated soft drink, juice, liquid dairy, liquid condiment and household & personal care products, etc.

The benefits:

Saving in the right areas

With efficient servo motors and sophisticated energy and blowing- air recovery systems, the BFC combi-

block can keep its energy and media requirements at a low level. By omitting the conveyors, you are also

saving on all areas of consumption for the container conveyor systems, from energy, air and conveyor

lubricant through to cleaning time savings.

Low space requirement

In practice, the BFC combi-block has proven itself to be a real space saver. For it needs up to 30 percent

less space than a layout containing a blow moulder/ filler block. Compared to a line made up of individual

machines, the space savings can be as much as 70 percent. This means you can save up to several hundred

square meters of hall space which you can then use for other purposes – or you could even save yourself the

bot her of building this space in the first place.

Powerful, malfunction-free production

The complete system is tuned from start to finish to achieve high performance. The best example of this is the labeller: It continually operates at its rated output and – thanks to its label selective operation is not

even distracted by gaps in the bottle flow.

Minimum operator involvement

With the BFC combi-block, the entire process from stretch blow molding right through to the capping

of the containers can be looked after by just one person. For all of its machines are controlled from a central

touch-screen.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\