Product Specification

| Condition | 新的 |

| Brand | HUAXIAMASTER |

| Warranty | 是的 |

Product Descriptions

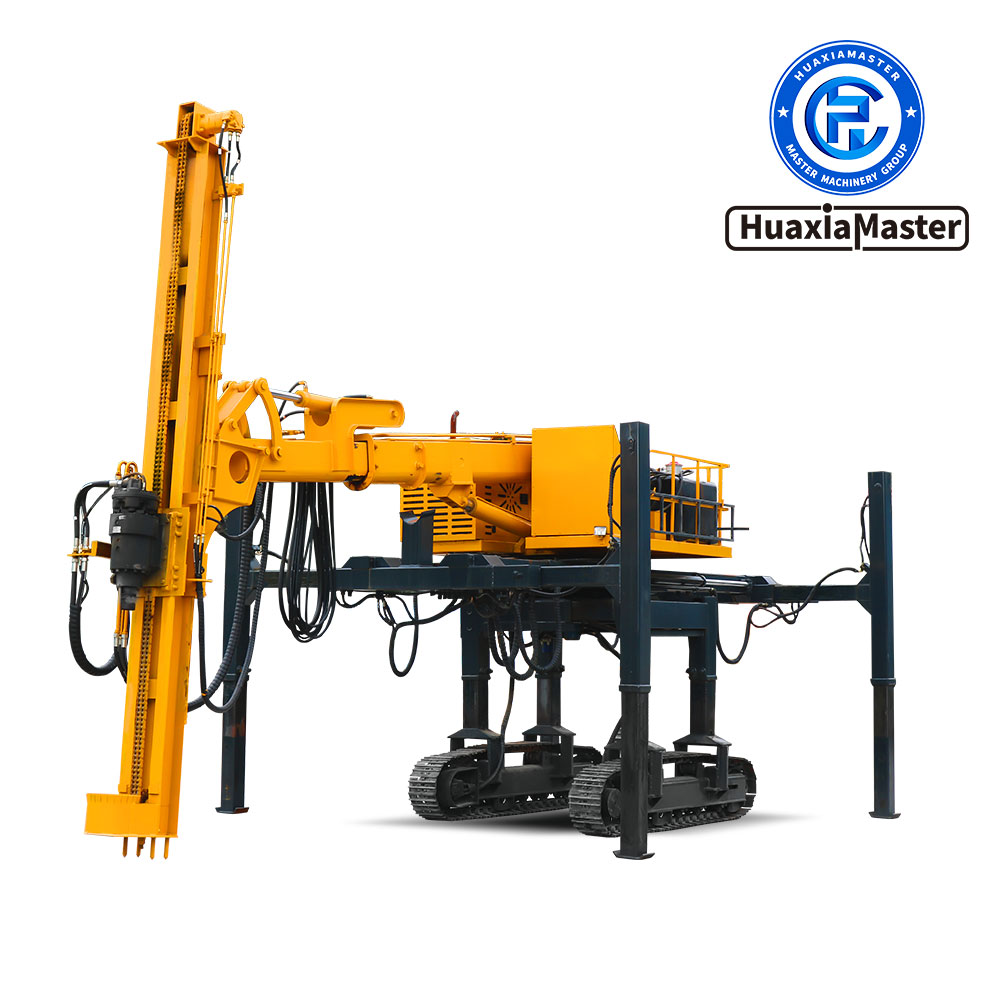

1. Introduction to GFQD All-terrain Photovoltaic Pile Driver

The GFQD all-terrain photovoltaic pile driver is a highly adaptable pile foundation construction equipment designed for the construction of photovoltaic power stations in complex terrains. It can complete pile foundation driving work in a variety of complex terrain conditions such as mountains, hills, deserts, swamps, etc. It can also choose spiral drilling, down-the-hole impact and other piling methods for construction operations according to different geological conditions. Its strong terrain adaptability, efficient piling ability and intelligent design can significantly improve construction efficiency and quality.

2. Features of GFQD All-terrain Photovoltaic Pile Driver

2.1 It adopts an all-terrain chassis design, and the two sides of the track chassis can be independently adjusted up and down, left and right, and can easily pass through complex terrains such as steep slopes, mud, sand, shallows, and subsidence depressions, and has extremely strong off-road capabilities.

2.2 Equipped with four hydraulic high outriggers, it can ensure that the drilling rig maintains horizontal stability in complex terrain such as slopes and gullies. After the hydraulic high outriggers are deployed, the machine body can move horizontally front and back and left and right, making it convenient for the pile driver to accurately locate the drilling holes on uneven ground and reduce equipment adjustment time.

2.3 The body and chassis are configured to rotate 360° and have a telescopic boom, allowing the drill to cover a larger operating area in all directions and reduce the number of times the equipment is moved; through flexible adjustment of the boom, drilling operations can be performed on different terrain gradients at the same time.

2.4 The strong terrain adaptability reduces the time and cost of terrain preparation in the early stage of the project, improves construction efficiency, and reduces the damage caused by construction to the ecological environment.

2.5 The use of advanced hydraulic system and power system ensures that it remains stable and reliable even in high-load operations.

2.6 Equipped with advanced intelligent control system and centralized control on the operating console, the operation is simpler.

2.7 The overall welding of the equipment is rigorous, and the wear-resistant parts adopt heat treatment technology to avoid structural deformation, ensuring stable operation under harsh construction conditions, with a long service life and low failure rate.

3. Parameters of GFQD All-terrain Photovoltaic Pile Driver

Pile driver model | GFQD-3000 | ||

Machine parameters | Track shoe width | 300mm | |

Gradeability | 30° | ||

Walking speed | 2-3km/h | ||

L*W*H | 4200*2200*3500mm | ||

weight | 9T | ||

Hydraulic outriggers | 4*1.5m/customizable | ||

Body forward and backward translation | 1m/customizable | ||

Body shift left and right | 1.5m/customizable | ||

Tracks can be extended up and down | Max 0.6m/customizable | ||

Single-side crawler can be extended up and down | Max 0.3m/customizable | ||

Powertrain | Diesel engine | 4108 four cylinder | 6108 six cylinder |

Rated Power | 78kW | 92kW | |

Hydraulic system | Power head | Internal five-star motor power head | |

Main pump model | 40/40/32 | ||

Main pump speed | 2000-2400r/min | ||

Main pump pressure | 20Mpa | ||

Main valve flow | 100L/min | ||

Maximum Torque | 8000-18000N.m | ||

Operation efficiency | Extendable radius of big arm | 8m | |

Drilling rack travel | 4000mm | ||

Compensation stroke | 1000mm | ||

Auger drilling diameter | 300mm/customizable | ||

Auger drilling depth | 0-3000mm | ||

Pneumatic drilling diameter | 90~400mm | ||

Pneumatic drilling depth | 1000~10000mm | ||

Note: Products are constantly being improved. Any changes will not be notified separately. Please refer to the actual product.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\