Product Specification

Product Descriptions

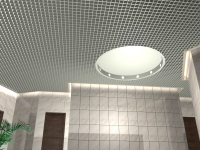

"Reliable-瑞立保" Aluminium Honeycomb Panels are mainly used for interior and exterior decoration of modern large-scale and high-rise buildings. Made with premium raw materials and precise craftsmanship, its surface is treated with advanced pre-rolled fluorocarbon coating, ensuring colour stability for up to 30 years.Using a dual-component high-polymer epoxy film and modified epoxy resin, the panels are manufactured in a fully enclosed, dust-free environment with automated honeycomb panel production equipment under high temperature and pressure. This results in stronger bonding, greater flexural resistance, improved flatness, and more reliable quality.Custom shapes such as curved, stepped, and trapezoidal panels can be produced according to architectural design requirements. All special shapes like arcs, L-shaped, and U-shaped panels are formed in one piece using dedicated moulds. Only aluminium coils from the same batch are used for each project to ensure colour consistency with no visible difference.These panels are high-quality, lightweight, high-strength, and visually luxurious, making them a premium, eco-friendly decorative material.

| Raw Materials | |

| Aluminium Face Panel | Mainly made from high-quality 3003H24 alloy aluminium sheet or 5052AH14 high-manganese alloy aluminium sheet, with a thickness of 0.7–1.5mm and fluorocarbon roll-coated surface. |

| Aluminium Back Panel | The back panel thickness ranges from 0.5 – 1.0mm. |

| Aluminium Honeycomb Core | Uses hexagonal 3003H18 aluminium honeycomb core, with aluminium foil thickness of 0.04–0.07mm and cell size of 5–6mm. |

| Adhesive | Utilises dual-component high-polymer epoxy film and dual-component modified epoxy resin. |

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\