Product Specification

| Condition | 新的 |

| Brand | HUAXIAMASTER |

| Warranty | 是的 |

| Power(W) | 132000 |

| Weight(KG) | 9500 |

| Type | 岩芯钻机 |

Product Descriptions

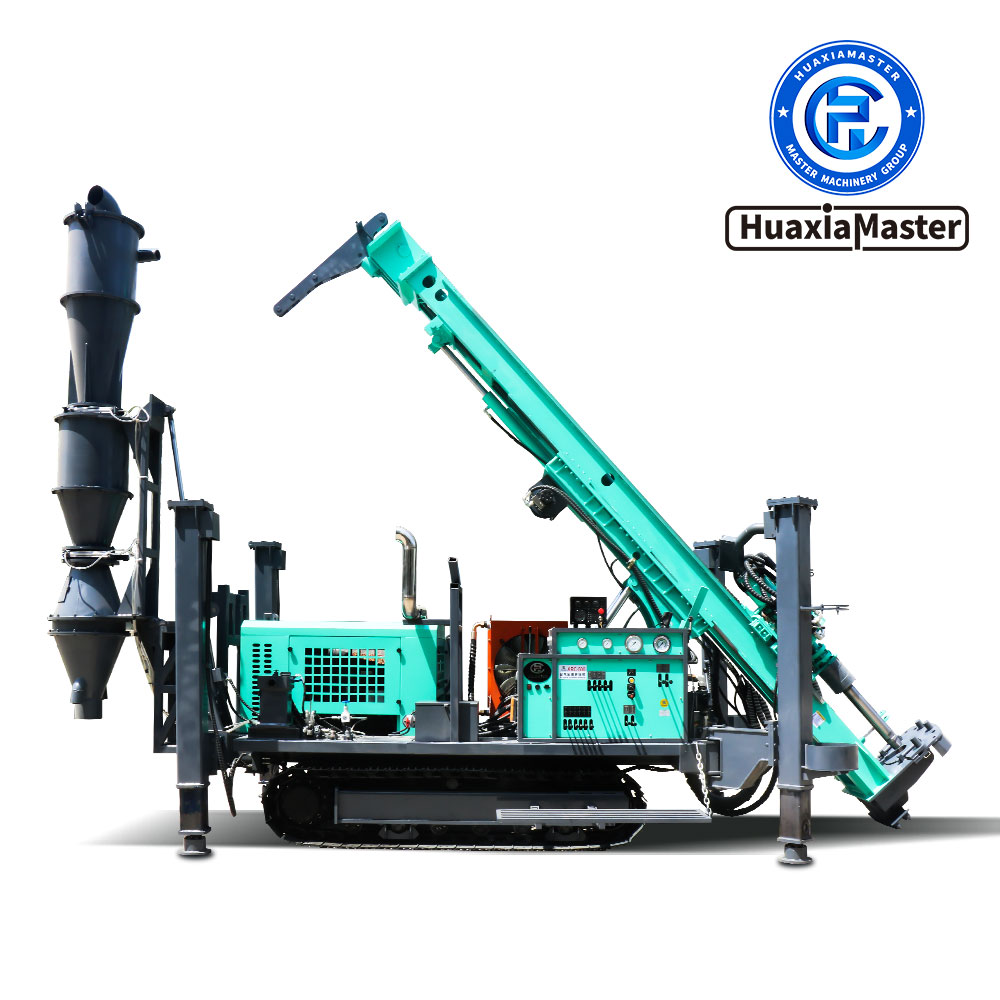

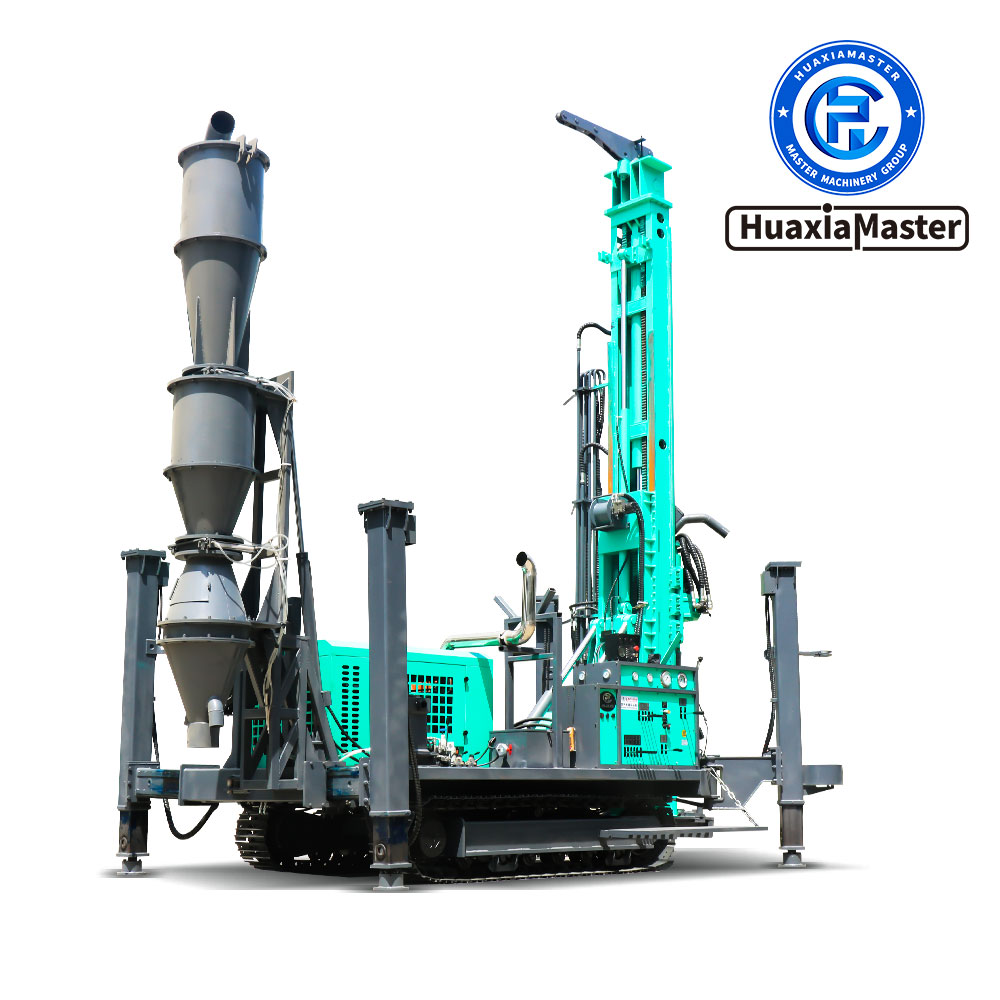

ARC Series Air Reverse Circulation Drilling Rig

1、Introduction to ARC Series Air Reverse Circulation Drilling Rig

ARC series air reverse circulation drilling rig is a new, efficient and environmentally friendly geological drilling equipment. It uses the latest air reverse circulation drilling technology from Master Research Institute, compressed air is used as the circulating medium to quickly discharge,the cuttings from the bottom of the hole through reverse circulation. Rock cuttings and dust are effectively collected and sorted through dust collectors,avoid sample contamination,ensure the accuracy of sample data. The drilling rig is mainly used in mineral exploration, hydrogeological exploration, engineering geological exploration and other fields, suitable for various geographical environments,including complex environments such as thin air at high altitudes, thick permafrost, and abundant groundwater. It is the preferred equipment for geological exploration drilling and other deep hole operations.

2、Features of ARC Series Air Reverse Circulation Drilling Rig

2.1 Efficient drilling: The air reverse circulation drill uses a closed circulation system to quickly discharge cuttings, reduce repeated crushing, and significantly increase drilling speed.

2.2 High sample quality: The rock chip dust samples obtained through air reverse circulation drilling are free from contamination, easy to classify and track, and can accurately locate the mineralization location.

2.3 Green and environmentally friendly: Using compressed air as the circulating medium, compared with traditional mud drilling rigs, it does not require a large amount of water and chemicals during the construction process, reducing pollution to the environment.

2.4 Full hydraulic operation: drilling rig lifting, power head rotation and feeding, drill rod connection and unloading and other actions are all realized by the hydraulic system, which greatly reduces labor intensity and improves construction efficiency.

2.5 Low maintenance cost: The air reverse circulation drilling rig has a simple structure, and key components are made of high-strength materials with strong wear resistance and corrosion resistance, which reduces the replacement frequency of wearing parts and has low maintenance costs.

2.6 Reliable power: adopt big brand diesel engine, strong power, stable performance and perfect after-sales service.

3、Parameters of ARC Series Air Reverse Circulation Drilling Rig

Drilling rig model | ARC-200 | ARC-300 | ARC-500 | ARC-800 | ARC-1200 | |

Overall machine parameters | Vehicle weight | 6T | 7.5T | 9.5T | 17T | 23T |

Shipping dimensions | 6000*1750*2350mm | 6750*2200*2550mm | 6750*2200*2650mm | 10500*2250*3300mm | 11500*2250*3400mm | |

Chassis | Engineering steel tracks Hydraulic walking chassis | Engineering steel tracks Hydraulic walking chassis | Engineering steel tracks Hydraulic walking chassis | Engineering steel tracks Hydraulic walking chassis | Engineering steel tracks Hydraulic walking chassis | |

Track ground length | 2150mm | 2500mm | 2500mm | 7000mm | 8000mm | |

Track chassis width | 1700mm | 1800mm | 1800mm | 2250mm | 2250mm | |

Hydraulic high outriggers | 4 | 4 | 4 | 4 | 4 | |

Machine power | Yuchai four-cylinder diesel engine | Yuchai six-cylinder diesel engine | Cummins six-cylinder diesel engine | Weichai six-cylinder diesel engine | Weichai six-cylinder diesel engine | |

Host power | 77.3kW | 110kW | 132kW | 176kW | 220kW | |

Technical parameters | Applicable rock strength | F=6~20 | F=6~20 | F=6~20 | F=6~20 | F=6~20 |

Drill pipe diameter | Φ89/Φ102 | Φ89/Φ102/Φ114 | Φ89/Φ102/Φ114 | Φ102/Φ114/Φ127 | ||

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\